Novelty of COIA's system

What is the novelty of COIA's system?

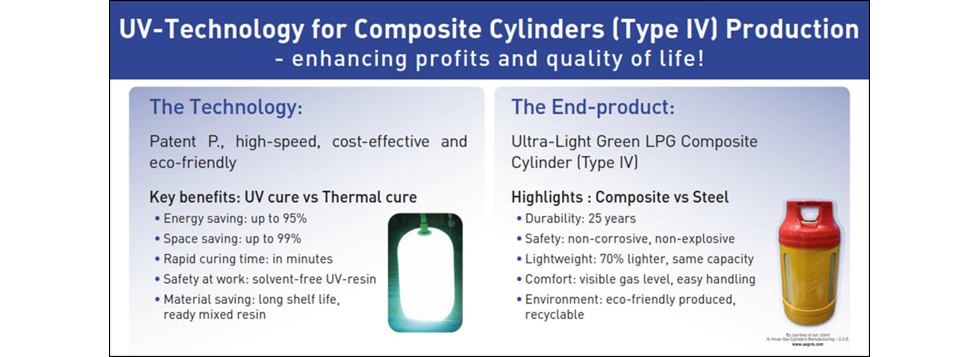

We have 25 years experience in manufacturing and processing of composites with fast cure UV-resins utilising State-of-the-Art, eco-friendly & cost-effective UV-Technology.

Superiority of COIA UV-system to conventional old thermal curing:

- Sustainable energy saving ~ 95%

- Space saving ~ 99%

- Higher productivity and quality

- Rapid curing speed of 1 minute/cylinder instead of 2-4 hours

- Solvent-free UV-Resin (no hardener, No VOC's, no hazardous fumes) with extended pot and shelf life of 2 years instead of few hours

- No need for additional resin mixing station and ex-proof air ventilation

All above figures will have positive effects on the manufacturing cost reduction that leads to higher margins and competitive sales prices of the cylinder.

Our plant concept reaches a yearly production quantity of multiple of 500,000 cylinders.

The current yearly capacity of the conventional (expensive and environmentally harmful) thermo system is approx. 1.5 million pieces.

The worldwide yearly demand for LPG tanks however is 128 million pieces.

So what are you waiting for?

Contact us

COIA GmbH

Hasenhägweg 73

D-63741 Aschaffenburg

Fon: +49 (0)6021 - 3487 - 0

Mail: info@coia.de

Member of WLPGA

The World LP Gas Association (WLPGA) is the authoritive voice of the global LP Gas industry representing the full LP Gas value chain.

High Quality Standards

Our UV-curable materials are environmental friendly and do comply with RoHS 2011/65/EU (former 2002/95/EG) regulation and are free of Silicone, Halogen and Solvents / VOC’s.